A marker is used in the production process.

Since most times (especially when using overseas factories) a marker gets done by the factory many fashion designers are not quite familiar with it so we thought we’ll help you with that.

So what is a marker?

A marker is what the cutter uses when cutting fabrics in production.

It is a long paper with all the pattern pieces printed on it (by size and fabric sections) which the cutter then lays on top of the fabrics and that is what he will follow when cutting the fabrics.

A marker is normally created digitally, using a cad program for grading and marking, and then gets printed out with a plotter as a long paper (length will depends on the number and length of the pattern pieces and the different fabric sections in that style).

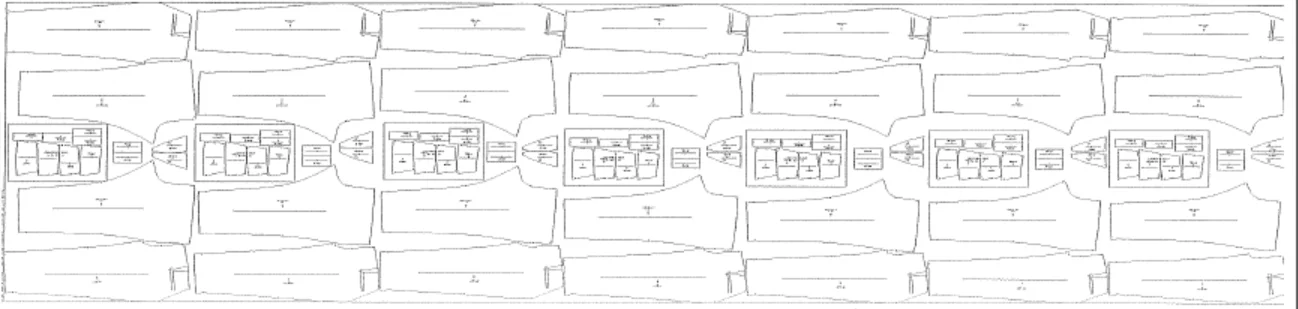

Here is a photo of what marker looks like:

This is a marker for pants, you can see how the pattern pieces are organized by sizes.

To better understand how a marker works and its purpose, let’s look at the production cycle and see where and how it fits in:

The first step is to have your production pattern fitted, finalized and ready for production.

Then the next step will be grading the pattern to the other sizes that you will be producing.

Once the grading is done the next step would be making a marker for the style.

When making the marker the grader will arrange the patterns pieces by size and fabric sections (re: self, combo, lining, fusible etc.), and will position them in the most compacted way in order to minimize fabric consumption.

Once the marker is done the fabric can be cut.

*** Only once a marker is made you will get an exact yield of fabric consumption.

The Cutter follows the marker when laying out the plies for cutting.

This is what a finish cut looks like, the cutter cut the pattern pieces following the marker.

By using the marker the cutter does not need to spend the time on laying out the pattern pieces himself, the marker has them all laid out and organized for him, and more so they are organized is the easiest and fastest way for the cutter to cut to maximize the cutting productivity process .

*** A marker is done for the specific width of the fabric that is being cut. So for example, If you are producing the same exact pattern but in 2 different fabrics that each have a different cutable fabric width, than you will need to make a separate marker for each fabric if you want to get the best fabric yield from each of these fabrics.

Once it's used for cutting the physical marker will not be usable anymore, however the digital file is still exist so for re-cuts the cutter will just need to get a new copy of the marker printed.

There are different ways and strategies to reduce fabric consumption in a marker, but these all depends on the cutable width of the fabric, how many units and sizes are you planing to cut, and if the fabric has a direction, print placement or matching.